Product Description

NEW Edwards nXDS6i 100 - 127 V, 200 - 240 V, 1ph 50/60 Hz

Click Here for Manual

nXDS improves on legacy XDS pumps by offering increased pumping speeds, combined with lower ultimate pressures, lower power consumption and lower noise. Gas ballast allows for pumping of condensable vapours including, water, solvents, dilute acids and bases. nXDS pumps also feature the latest in tip seal technology giving significantly longer life between tip seal changes. Integrated inverter drive with auto sensing voltage input delivers optimized pumping performance globally. nXDS pumps are designed to be completely field serviceable.

Technical Data

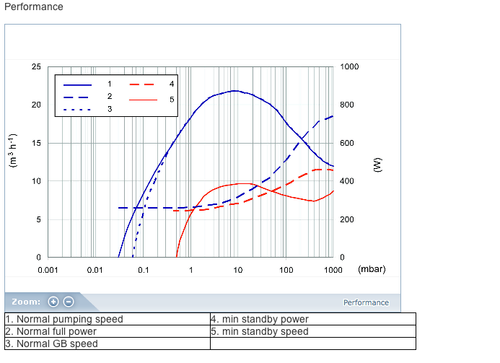

| Nominal rotational speed | 1800 rpm |

| Displacement | 6.8 m3h-1 / 4.0 ft3min-1 |

| Peak pumping speed | 6.2 m3h-1 / 3.6 ft3min-1 |

| Ultimate vacuum (total pressure) | 0.020 mbar / 0.015 Torr |

| Minimum standby rotational speed | 1200 rpm |

| Speed control resolution (percentage of full rotation speed) | 1% |

| Pumping speed at minimum rotational speed | 4.1 |

| Maximum continuous inlet pressure | 200 mbar |

| Motor power 1-ph | 260 W |

| Power connector 1-ph | IEC EN60320 C13 |

| Recommended fuse | 10A, 250Vac rms |

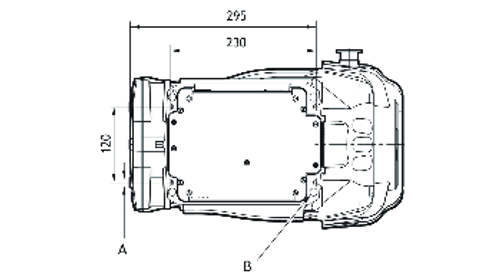

| Weight | 26.2 kg / 58 lb |

| Inlet flange | NW25 |

| Exhaust flange | NW25 |

| Noise level | 52 dB(A) |

| Vibration at inlet flange | < 4.5 mms-1 (rms) |

| Leak tightness (static) | < 1x10-6 mbar ls-1 |

| Operating temperature range | 10 to 40 °C / 41 to 104 °F |

Features and Benefits

- Lubricant-free within the vacuum envelope and hermetically sealed means totally clean and dry vacuum to prevent cross contamination

- No atmosphere to vacuum shaft seals means bearings are completely isolated, which prevents process attack and means the bearings run cooler and last longer

- Simple single sided scroll arrangement combined with an innovative motor and bearing design allows for easy field service with a minimum of special tooling for low cost of ownership and maximum up-time

- Improved motor and drive efficiencies for reduced power and cost of ownership

- Advanced interface provides a variety of traditional, analogue and digital control methods enabling remote control/monitoring via USB, RS232 or RS485

Applications

- General clean pumping applications

- Scanning Electron Microscopes - SEM

- Beam lines and high energy physics

- Backing turbo pumps

- Centrifuges, ultra-high speed

- Coating

- Cryogenics

- Degassing/curing - oil, epoxy resin

- Distillation/extraction/filtration

- Freeze drying

- Furnaces

- Gel drying

- Laboratory bench top vacuum

- Lasers, gas recovery and recirculation

- Leak detectors, Helium

- Load locks and transfer chambers

- Rare gas recirculation

- Rare gas recovery

- Refrigeration manufacture

- Research and development

- Rotary, centrifugal evaporators

- SEM/FIB (ion beam repair)

- Solvent recovery

- Surface science instruments