Product Description

Reconditioned Alcatel 2015SD Vacuum Pump. 11CFM. 115/208v 1/2HP

1 year warranty.

Click Here For Product Manual

Click Here For Product Manual

Rotary vane pumps from the Pascal Series for backing vacuum and medium vacuum

The two-stage Pascal rotary vane pumps are the result of decades of experience in the design and industrial production of vacuum pumps.

Rotary vane pumps for main vacuum applications

The pumps from the Pascal Series from Pfeiffer Vacuum with their high performance are used in the most demanding applications in industry, analytics and research & development. They are distinguished by their recognized high quality and reliability. Five versions of the lubricated Pascal pumps allow the optimal adjustment to different requirements.

The following versions are available:

- SD-version for all vacuum applications with non-corrosive gases

- I-version for the requirements of instrumental analytics

- C1-version for applications with aggressive or corrosive gases

- C2-version for harsh duty applications with the most aggressive pumping environment

Rotary vane pumps for simple integration in systems

The oil emission on the outlet is minimized through the optimal lubrication design. The integrated non-return system guarantees optimal leak-tight properties by design. The assignment of all operating elements and service accesses on the front side of the vane pumps guarantees a simple integration in systems. The compact models with a pumping speed between 5 and 21 m3/h are equipped with universal motors, which allow for worldwide usage. The configuration of the single stage motors occurs through a simple plug-in position. Three-phase motors of high capacity pumps guarantee compliance with international requirements for operating voltages, frequencies and standards.

Long-lasting rotary vane pumps

Just like all products from Pfeiffer Vacuum, with its robust design the Pascal Series is designed for maximum reliability and minimal maintenance. The external shaft seals can be easily exchanged without disassembling the pump. Thus, all pumps can be simply maintained in the field with the fitting original maintenance sets. A comprehensive selection of accessories like oil filters, condensate traps or dust filters add to the pump selection. Fitting lubricants with different viscosities guarantee the optimal and long-lasting operation in different applications. In order to obtain the desired final pressure, the operating fluid must have a very low saturation pressure and a special viscosity in the internal temperature range of the pump.

Advantages

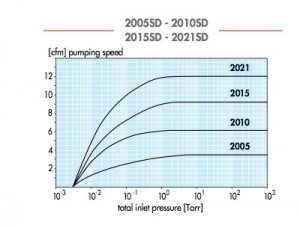

- Complete range from 5 m3/h to 60 m3/h

- Different versions in order to fulfill customer requirements

- Known worldwide for high quality and reliability

- Simple application and integration

- Simple maintenance

- Design with low oil back-streaming

- Optimized global tightness concept

- CE-/UL-/CSA-permitted motors

- Comprehensive oils and accessories range

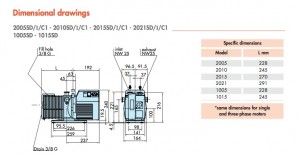

| Flange (in) | DN 25 ISO-KF |

| Flange (out) | DN 25 ISO-KF |

| Mains requirement: voltage 50 Hz | 180-254 V |

| Mains requirement: voltage 60 Hz | 180-254 V |

| Operating fluid | Mineral oil |

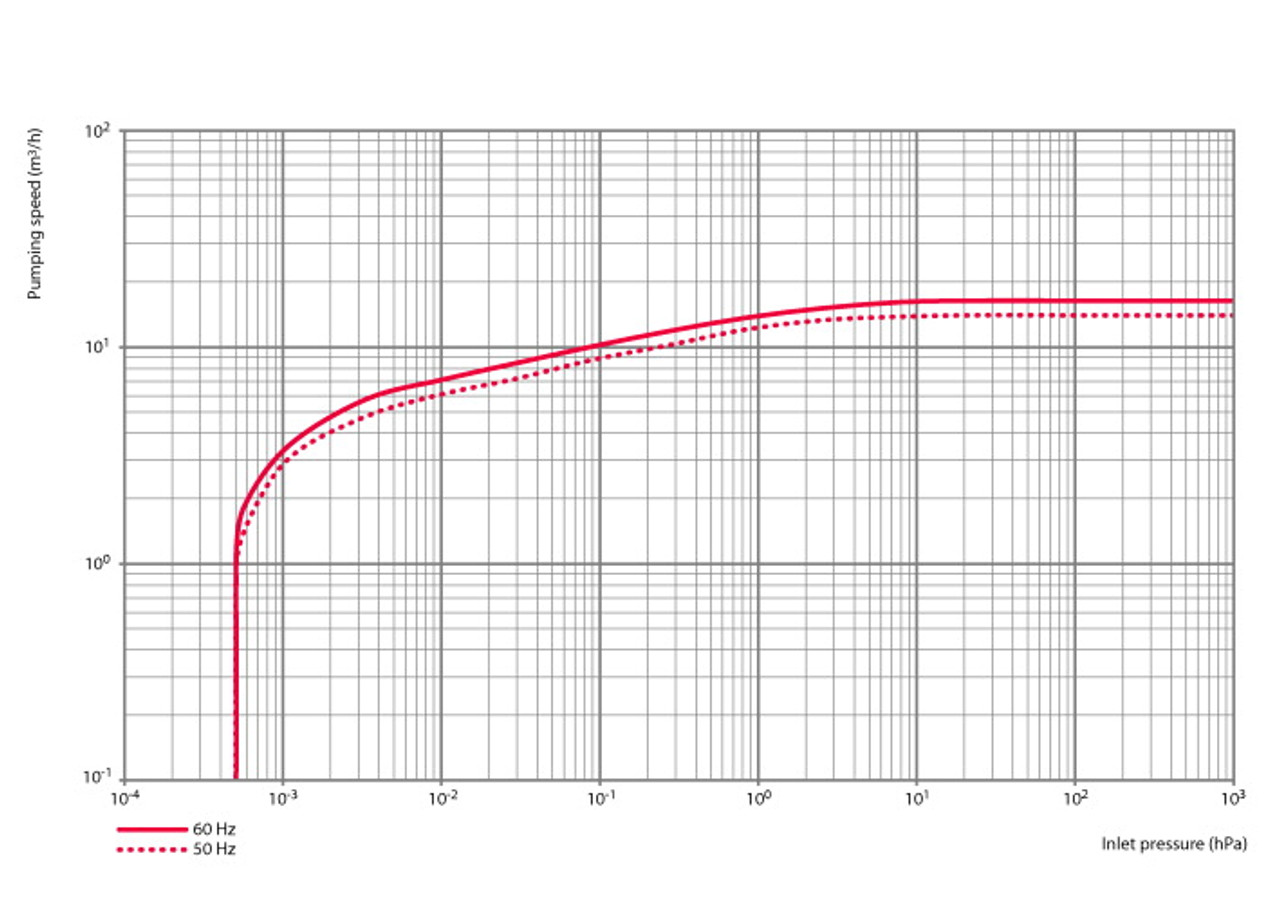

| Pumping speed at 50 Hz | 14 m3h |

| Pumping speed at 60 Hz | 16.5 m3h |

| Rated power 50 Hz | 0.45 kW |

| Rated power 60 Hz | 0.55 kW |

| Ultimate pressure | 5 · 10-4 hPa |

| Ultimate pressure with gas ballast | 10-2 hPa |

| Version | Standard |

| Weight | 27 kg |

Ultimate pressure according to PNEUROP

Applications

- Analytical instruments - LCMS

- Automotive

- Beam lines and high energy physics

- Centrifuges, ultra-high speed

- Coating

- Cryogenics

- Degassing/curing - oil, epoxy resin

- Distillation/extraction/filtration

- Freeze drying

- Furnaces

- Gas bottle filling/emptying

- Gel drying

- Glove boxes, ovens

- Laboratory bench top vacuum

- Leak detectors, Helium

- Load locks and transfer chambers

- Refrigeration manufacture

- Research and development

- Rotary, centrifugal evaporators

- Scanning electron microscopes - SEM

- SEM/FIB (Ion beam repair)

- Solvent recovery

- Surface science instruments

- Turbomolecular backing pumps

- TV manufacturing / light bulb manufacture

Alcatel Pump Rebuild Process:

-

Every Alcatel vacuum pump we sell goes through our comprehensive rebuild process at our location.

- Each pump is fully disassembled and all parts are cleaned and decontaminated with our multi-step process to ensure all contaminants are removed.

- All parts are inspected for wear and replaced as necessary.

- Damaged or worn parts are replaced.

- All O-rings, seals, springs, and gaskets replaced.

- Complete New repair kit installed.

- Motor tested.

- Assembled and tested with multiple flushes of new oil.

Our Rebuilt Alcatel Pumps comes with a full 1 year warranty for parts and labor.