Product Description

Atlas Copco GLS500 Rotary Piston Vacuum Pump- NEW

Better dependability with minimal maintenance

With over 10,000 units sold in 80 years, the Atlas Copco GLS rotary piston pump sets the standard for performance and reliability as the industry’s most efficient, space-saving design.

As part of the Atlas Copco Group, Stokes Vacuum continues to innovate oil-lubricated rotary piston pumps. The GLS has been improved, upgraded and fine-tuned. It delivers even better dependability and productivity combined with minimal

maintenance and process downtime, especially crucial in demanding applications such as the automotive or aerospace industry and their supply chains.

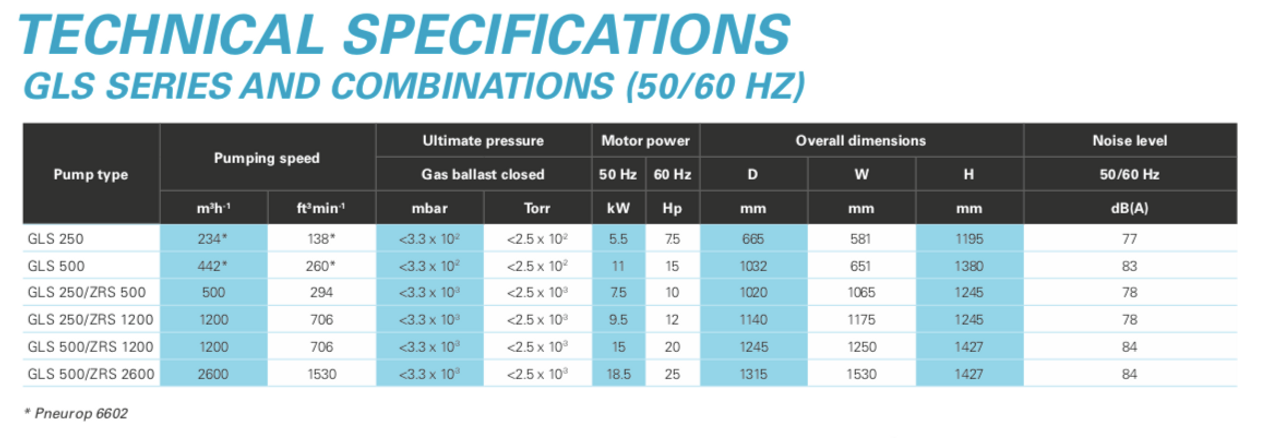

Designed compactly for maximum uptime with minimal moving parts and large clearance, the GLS rotary piston pump has advanced balancing that reduces vibration and is easy to maintain. Add a ZRS booster to the GLS to increase the pumping speed.

Every feature works towards providing you with exactly what you need. From a low lifecycle cost, to in-house service for extra peace of mind, to reliable operation.

Keeping in mind the automotive and aerospace industry and their supply chains, the GLS has been improved, upgraded and fine-tuned.

Reduced maintenance

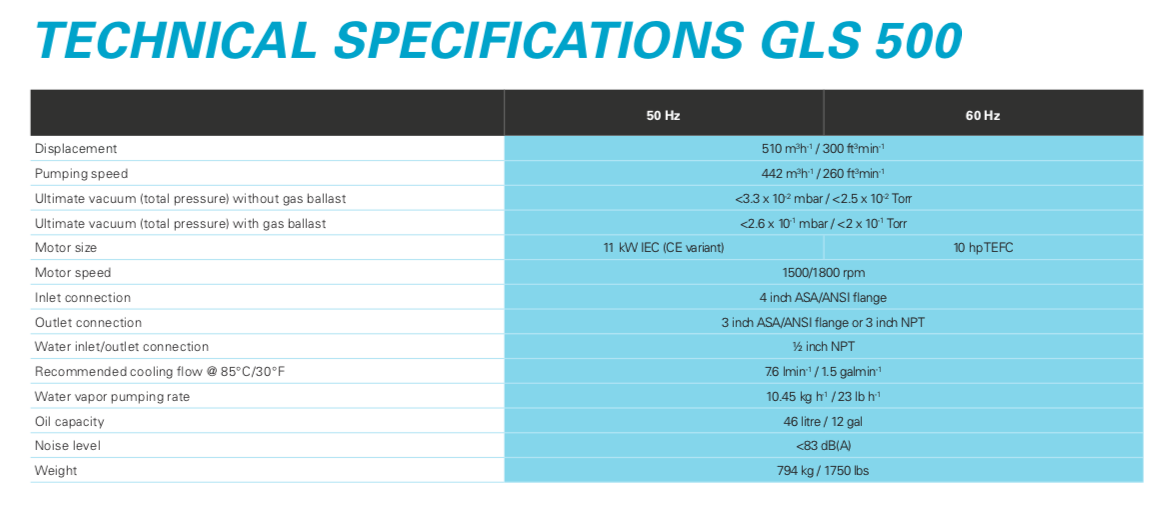

All GLS pumps are fitted with a water mizer to minimize the water consumption and optimize the running temperature. This brings extra reliability, a longer period between maintenance and a very low lifecycle cost.

State-of-the-art control

Lubrication of the internal components of the pumps is completely automatic. This pump is fitted with a 230/460 V coil for control of the oil solenoid valve which prevents the pump from flooding with oil in case of a power failure or loss of vacuum.

Reliable system protection

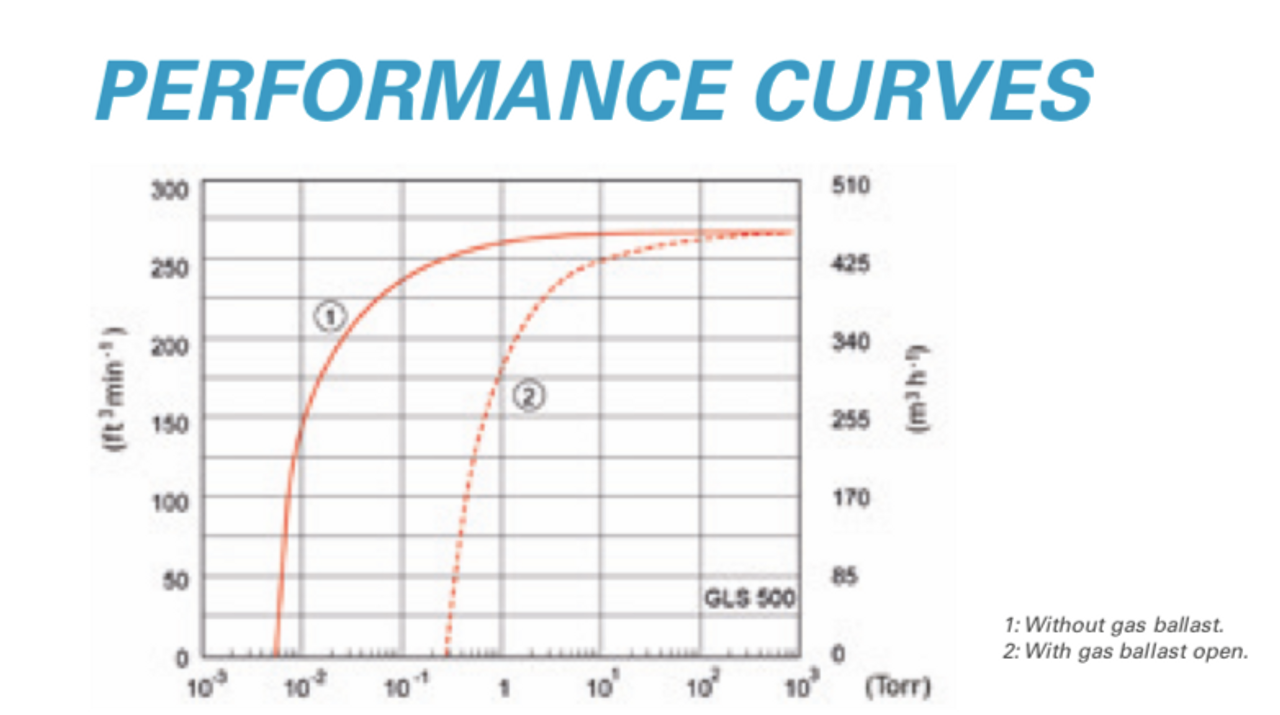

To allow pumping of high vapor loads, integral gas ballast is fitted. This is used to prevent condensation of the vapor carried by the pump gases.

Low lifecycle cost

Thanks to the slow rotational speed, reliability is optimum and lifecycle cost is low.

Features and Benefits

- Robust cast and ductile iron construction provides rugged reliable operation.

- Efficient design provides maximum uptime with minimal moving parts and large clearance.

- Low ultimate blank-off with pressures down to < 10-2Torr.

- New valve design virtually eliminates valve maintenance and noise.

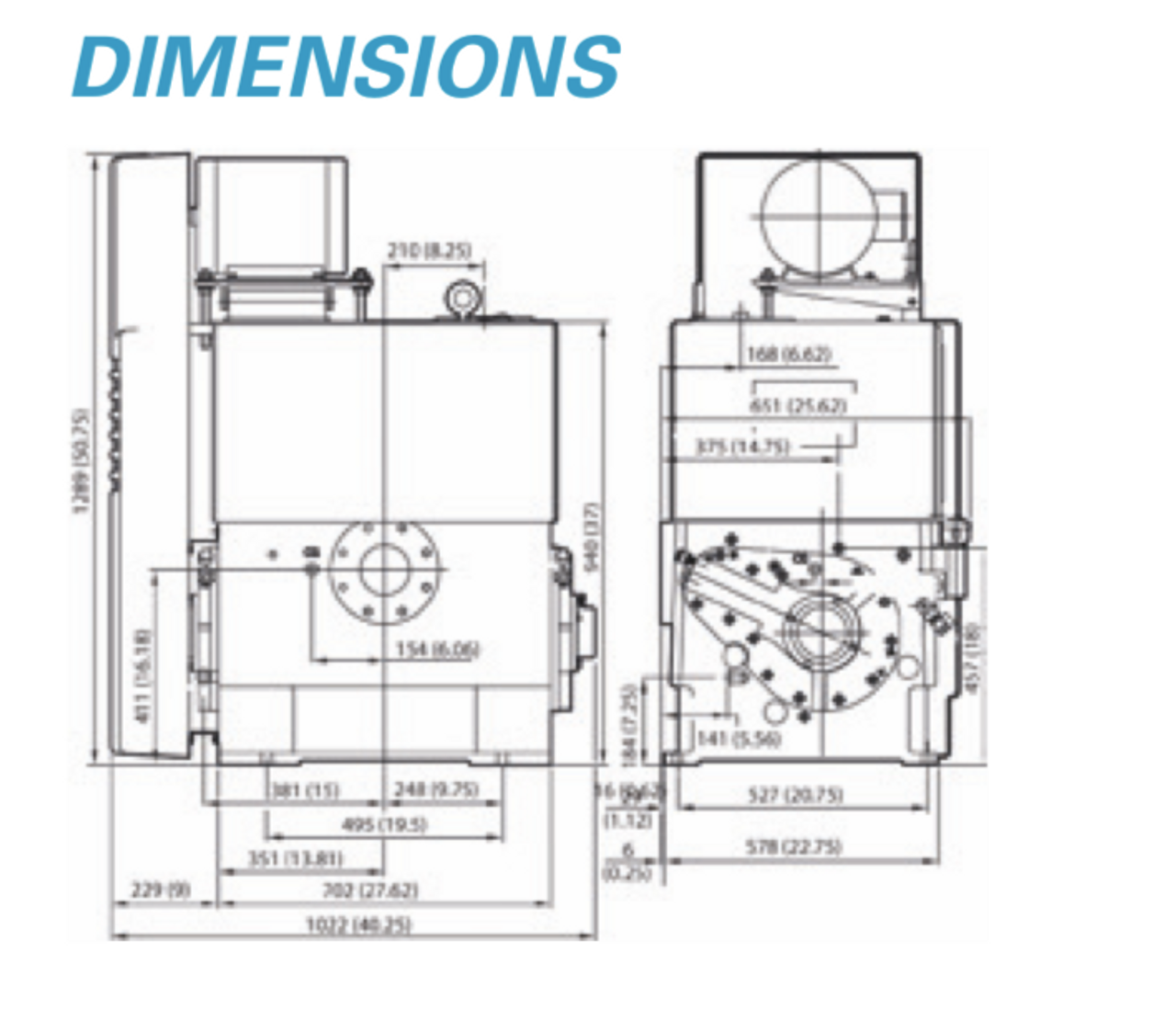

- Space saving design which saves up to 50 of valuable floor space.

- Complete and self-contained unit delivered ready to install.

- Automatic lubrication system provides proper flow of oil to bearings and sealing surfaces and prevents back flow into system.

- Controlled balancing reduces vibration to a practical minimum.

- Gas ballast as standard.

- Total capability includes the manufacturing and service capabilities to keep your equipment in top operation with a broad range of vacuum system accessories.

Technology

To allow pumping of high vapor loads, an integral gas ballast is fitted. This is used to prevent condensation of the vapor carried by the pump gases.

Applications

- Automotive

- Chemical processing

- General applications

- Heat treatment

- Leak detection

- Metallurgy

- PET processing

- Pharmaceuticals

- Transformer drying and cable fluid conditioning

- Vacuum coating

- Vacuum melting