Product Description

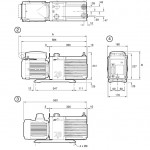

Reconditioned Edwards E2M30 Vacuum Pump.

23 CFM. 3 Phase

LIST PRICE OF NEW $8653 SAVE$$$$$$$$$$

We have these pumps at an unbelievable price. Get a reconditioned E2M30 pump for more than 50% less than the cost of a new pump. You get the same 1 year warranty as you would from the manufacturer of the pump. It is alos good to note that the Edwards E2M30 and the Edwards E2M28 are identical pumps. Both are great and have been an industry standard for years. Quiet and reliable performance make these a great choice.

We also stock many accessories for these pumps.

1 year warranty.

Technical Data

| Ultimate vacuum (total pressure) | |

| without gas ballast | 1 x 10-3 mbar / 7.5 x 10-4 Torr |

| with gas ballast | 1.5 x 10-2 mbar / 1.1 x 10-2 Torr |

| with Fomblin® | 1 x 10-2 mbar / 7.5 x 10-3 Torr |

| Inlet connection | NW25 flange |

| Outlet connection* | Nozzle 15 mm external Ø removable from 3/4 in BSP tapped hole |

| Max allowed pressure at outlet | 0.5 bar gauge / 7 psig |

| Max inlet pressure for water vapour | 30 mbar / 23 Torr |

| Max water vapour pumping rate | 0.7 kg h-1 |

| Operating temperature range | 13 – 40 °C |

| Weight | 44 kg / 97 lbs |

| Noise | 57 dB(A) @ 50 Hz |

| Oil capacity - max | 1.5 litre |

| Oil capacity - min | 1.2 litre |

| Recommended oil (supplied) | Ultragrade 19 |

* The PFPE are supplied with NW25 outlet connection

** Pumps listed with IEC connector only

The EM range of oil-sealed rotary pumps - renowned for its high ultimate vacuum, rapid pumping speed, quiet operation and ability to handle vapour - has become the industry standard laboratory and light industrialapplications.

The E2M28 pump is a two-stage, direct drive, sliding vane pump. The pump is oil sealed and designed for reliable, long-term operation in both laboratory and industrial environments. The pump is a freestanding unit with the drive provided through a flexible coupling by either a single-phase or three-phase (four-pole) motor.

Technology

Applications

-

Analytical instruments - LCMS

-

Automotive

-

Beam lines and high energy physics

-

Centrifuges, ultra-high speed

-

Coating

-

Cryogenics

-

Degassing/curing - oil, epoxy resin

-

Distillation/extraction/filtration

-

Freeze drying

-

Furnaces

-

Gas bottle filling/emptying

-

Gel drying

-

Glove boxes, ovens

-

Laboratory bench top vacuum

-

Lasers, gas recovery and re-circulation

-

Leak detectors, Helium

-

Load locks and transfer chambers

-

Refrigeration manufacture

-

Rotary, centrifugal evaporators

-

Solvent recovery

-

Surface science instruments

-

Turbomolecular backing pumps

- Each pump is fully disassembled and all parts are cleaned and decontaminated with our multi-step process to ensure all contaminants are removed.

- All parts are inspected for wear.

- Damaged or worn parts are replaced.

- All O-rings, seals, springs, gaskets replaced.

- Motor tested.

- Assembled and tested with multiple flushes of new oil.