Product Description

NEW E2M80 208-230/460V, 3-ph, 60Hz

Click Here for Manual

Edwards E2M80 vacuum pump is larger pump that handles larger applications while still keeping a relatively compact footprint. These pumps are the larger siblings in the E2M line and have a bunch of the same characteristics. They are also relatively quiet and have very little vibration for a pump that size. Compared to a simlar capacity piston pump, these are much smaller and quiter while giveing you outstanding performance. At we plan on being with you the life of the pump and not to disappear after the sale.

The Edwards E2M80 is also available in a PFPE version.

VPS stocks repair parts for ths pump!

Service also available!

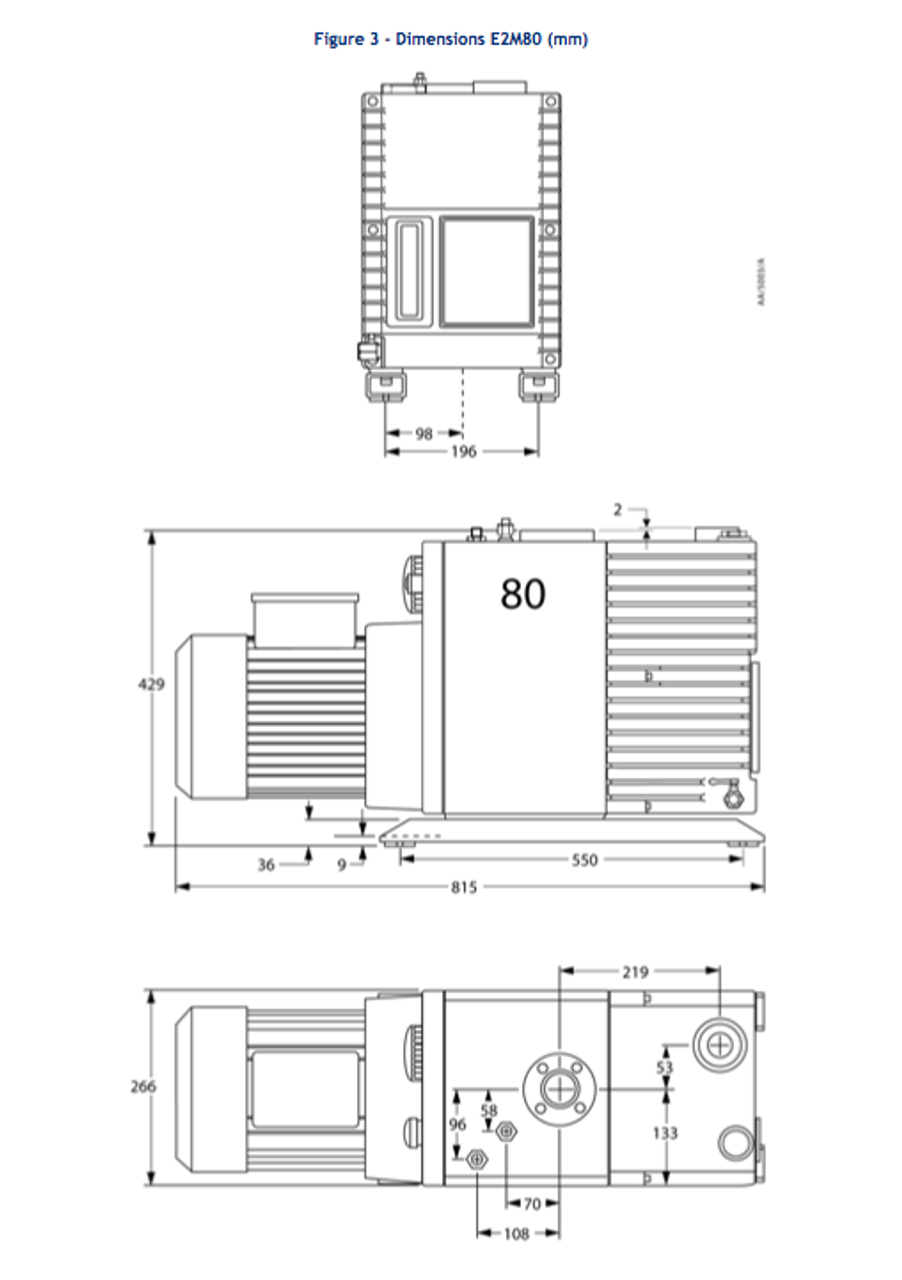

Edwards E2M80 Overview

This pump is suitable for most duties and is safe to handle non-flammable gases and vapours within the normal operating parameters of the pump.

Technical Data

| Displacement | |

| 50Hz | 80 m3h-1 / 47.1 ft3min-1 |

| 60Hz | 96 m3h-1 / 56.5 ft3min-1 |

| Speed (Pneurop) | |

| 50Hz | 74 m3h-1 / 43.6 ft3min-1 |

| 60Hz | 90 m3h-1 / 53 ft3min-1 |

| Number of stages | 2 |

| Ultimate vacuum (total pressure) | |

| Without gas ballast | 1 x 10-3 mbar / 7.7 x 10-4 Torr |

| With gas ballast | 7 x 10-3 mbar / 5.4 x 10-3 Torr |

| Ultimate with Fomblin® | |

| Without gas ballast | 1 x 10-2 mbar |

| Inlet connection | ISO40 |

| Outlet connection | 25 mm flange suitable for NW25 |

| Max outlet pressure | 0.5 bar gauge |

| Max inlet pressure for water vapour | 5 mbar / 3.8 Torr |

| Max water vapour pumping rate | 0.3 kg h-1 / 0.7 lb h-1 |

| Weight | 125 kg / 275 lb |

| Motor protection rating | IP55 |

| Motor power | |

| 50Hz | 2.2 kW / 3 hp |

| 60Hz | 3 kW / 4 hp |

| Standard oil capacity | |

| maximum | 6.3 litre / 6.7 qt |

| minimum | 4 litre / 4.2 qt |

| PFPE oil capacity | |

| maximum | 4.01 litre / 4.2 qt |

| minimum | 2.19 litre / 2.3 qt |

| Recommended oil | Ultragrade 70 |

| Noise level | 70 dB (A) |

Technology

Reliable system protection devices

Every pump has protection devices to prevent oil and air suck-back into the vacuum system if the pump stops while under vacuum. A variety of protection devices are used, depending on the pump size and cost, but emphasis is always placed on reliability and simplicity. When you use gas ballast on some of the pumps, you must use a solenoid operated gas ballast control valve to prevent air suck-back.

Positive Pressure Oil Lubrication

The E2M80 pumps incorporate a well proven positive pressure oil lubrication system which as been developed by Edwards to ensure correct lubrication in all duty modes and particularly to prevent oil starvation with high gas loads.

An integral oil pump ensures that a more than adequate oil flow is pumped throughout the stator/rotor assembly at all times.

This oil lubrication system means that the level of oil in the reservoir is less critical than with other pump designs. All pumps can operate with oil levels as low as 50-70% of the maximum. A full length, easily visible oil level sight glass allows you to conveniently monitor the oil level.

Gas Ballast Facility

The E2M80 pumps have a gas ballast valve. The valve is used to introduce a suitable gas into the stator during the compression stage: this prevents condensation of vapors inside the pump, dilutes and ejects corrosive gases and purges the oil of gases and vapors. Therefore, the use of gas ballast reduces oil degradation and pump corrosion.

Low Noise Levels

The E2M80 pumps maintain Edwards reputation for quiet operation pumps with a typical noise level of 70 dB(A).

Pumping Systems

The E2M80 pumps, with suitable accessories, can partner a variety of other types of pump in vacuum systems for industry and for research. A special feature of the E2M80 is the central vacuum inlet which enables you to fit a mechanical booster pump with a minimum overhang, to create compact combination pumping systems.

Easy Maintenance

The advanced lubrication system allows the EM pumps to work with wide oil level tolerances, which reduce the need to top-up the oil.

All E2M80 pumps are constructed with internal dowels, which reduce the need for skilled setting of tolerances, when the pump is dismantled. The pumps are designed so that all key components are easily accessible. The exhaust valve seals and oil distributor seals are exposed after the top cover is removed. The shaft seal can be replaced quickly without stripping down the pump.

Applications

-

Vacuum metallurgy processes

-

Thin film coating technologies

-

Pharmaceutical freeze drying

-

Refrigeration and air conditioning system evacuation, drying, and backfilling

-

Transformer and cable drying and impregnation, insulating oil treatment plant

-

Lamp manufacture

-

Cryogenic vessel evacuation

-

Vacuum drying and distillation in chemical industries

-

Semiconductor device manufacture

- Backing pump for high vacuum applications

A36502982