Product Description

Reconditioned Edwards RV5 1-phase 115/230 V. 4 CFM Rotary Vane Pump

Click Here for Manual

1 year warranty.

Overview

Technical Data

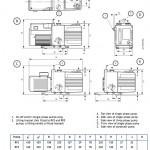

| Displacement | |

| 50Hz | 5.8 m3h-1 / 3.4 ft3min-1 |

| 60Hz | 7.0 m3h-1 / 4.1 ft3min-1 |

| Speed (Pneurop 6602) | |

| 50Hz | 5.1 m3h-1 / 3.0 ft3min-1 |

| 60Hz | 6.2 m3h-1 / 3.7 ft3min-1 |

| Ultimate pressure | 2.0 x 10-3 mbar / 1.5 x 10-3 Torr |

| Ultimate pressure GB I | 3.0 x 10-2 mbar / 2.3 x 10-2 Torr |

| Ultimate pressure GB II | 1.0 x 10-1 mbar / 7.5 x 10-2 Torr |

| Ultimate Pressure with Fomblin® | 2.0 x 10-2 mbar / 1.5 x 10-2 Torr |

| Max inlet pressure for water vapour | 50 mbar / 38 Torr |

| Max water vapour pumping rate – GB I | 60 gh-1 |

| Max water vapour pumping rate – GB II | 220 gh-1 |

| Max allowed outlet pressure | 1 bar gauge / 14 psig |

| Max allowed inlet and gas ballast pressure | 0.5 bar gauge / 7 psig |

| Motor power 50/60Hz | 450 / 550W |

| Power connector 1-ph | IEC EN60320 C13 |

| Nominal rotation speed 50/60Hz | 1500 / 1800rpm |

| Weight (without oil) | 25 kg / 55 lb |

| Oil capacity min/max | 0.42/0.7 litres |

| Recommended oil | Ultragrade 19 |

| Inlet flange | NW25 |

| Exhaust flange | NW25 |

| Noise level | 48 dB(A) @ 50 Hz |

| Operating temperature range | 12 – 40 °C |

Technology

In its high vacuum mode, the RV pump is ideal for analytical instruments, electron microscopes, physics research, backing turbo pumps, TV tube pumping and leak detection applications. Configure the same pump in the high throughput mode, and it becomes suitable for mass spectrometer inlet systems, distillation, laboratory furnaces, backing vapor pumps, solvent concentration, freeze drying and other drying applications.

The simple to use mode selector and accessible, three-position gas ballast control allow the pump to be reconfigured at any time, even when the pump is running.

Features and Benefits

-

48 dBA and intrusive frequencies minimised.

-

Dual mode. Suitable for high throughput and high vacuum applications.

-

Easy-to-use gas ballast.

-

Fast acting inlet valve for system protection.

-

High torque, dual voltage/dual frequency motor, electronic start relay.

-

Efficient high pressure lubrication.

-

Oil-tight with printed gaskets, effective shaft seals.

-

Clamped-in sight glass.

-

Oil box well contains filling spills.

-

Hi-tech polymer blades, large diameter, easy-clean oil passages.

-

Consistent, built-in quality, cast bar construction.

Applications

-

Analytical instruments

-

Centrifuges, ultra-high speed

-

Coating

-

Degassing/curing - oil, epoxy resin

-

Distillation/extraction/filtration

-

Freeze drying

-

Furnaces

-

Gas bottle filling/emptying

-

Gel drying

-

Glove boxes, ovens

-

Laboratory bench top vacuum

-

Leak detectors, Helium

-

Load locks and transfer chambers

-

Refrigeration manufacture

-

Research and development

-

Rotary, centirfugal evaporators

-

Scanning electron microscopes - SEM

-

SEM/FIB (ion beam repair)

-

Solvent recovery

-

Surface science instruments

-

Turbomolecuar backing pumps

Edwards Pump Rebuld Process:

Every Edwards vacuum pump we sell goes through our comprehensive rebuild process at our location!

- Each pump is fully disassembled and all parts are cleaned and decontaminated with our multi-step process to ensure all contaminants are removed.

- All parts are inspected for wear.

- Damaged or worn parts are replaced.

- All O-rings, seals, springs, gaskets replaced.

- Motor tested.

- Assembled and tested with multiple flushes of new oil.

Our Rebuilt Edwards Vacuum Pumps comes with a full 1 year warranty for parts and labor.