Product Description

NEW Edwards XDS35i

1-phase 100-120/200-230 v. 25 CFM Dry Scroll Pump

A73001983

Technical Data

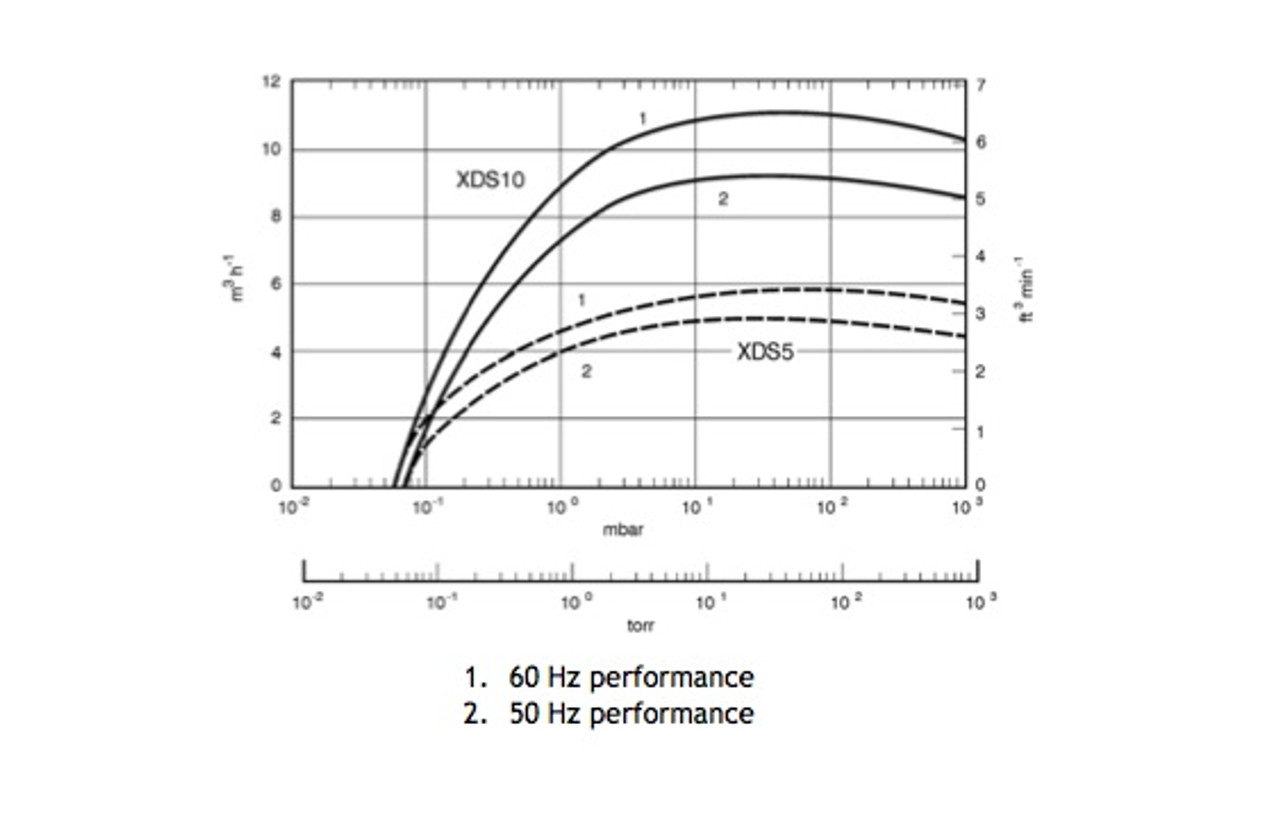

| Displacement 50 or 60Hz | 43 m3h-1 / 25 ft3min-1 |

| Peak pumping speed 50 or 60Hz | 35 m3h-1 / 21 ft3min-1 |

| Ultimate vacuum (Total pressure) | 1 x 10-2 mbar / 8 x 10-3 Torr |

| Max inlet pressure for water vapour | 35 mbar / 23 Torr |

| Max water vapour pumping rate – GB I | 70 gh-1 |

| Max water vapour pumping rate – GB II | 240 gh-1 |

| Max allowed outlet pressure | 0.2 bar gauge / 2.9 psig* |

| Max allowed inlet and GB pressure | 0.5 bar gauge / 7 psig |

| Motor power | 0.52kW |

| Power connector | IEC EN60320 C19 |

| Nominal rotation speed | 1750 rpm |

| Weight | 48 kg / 105 lb |

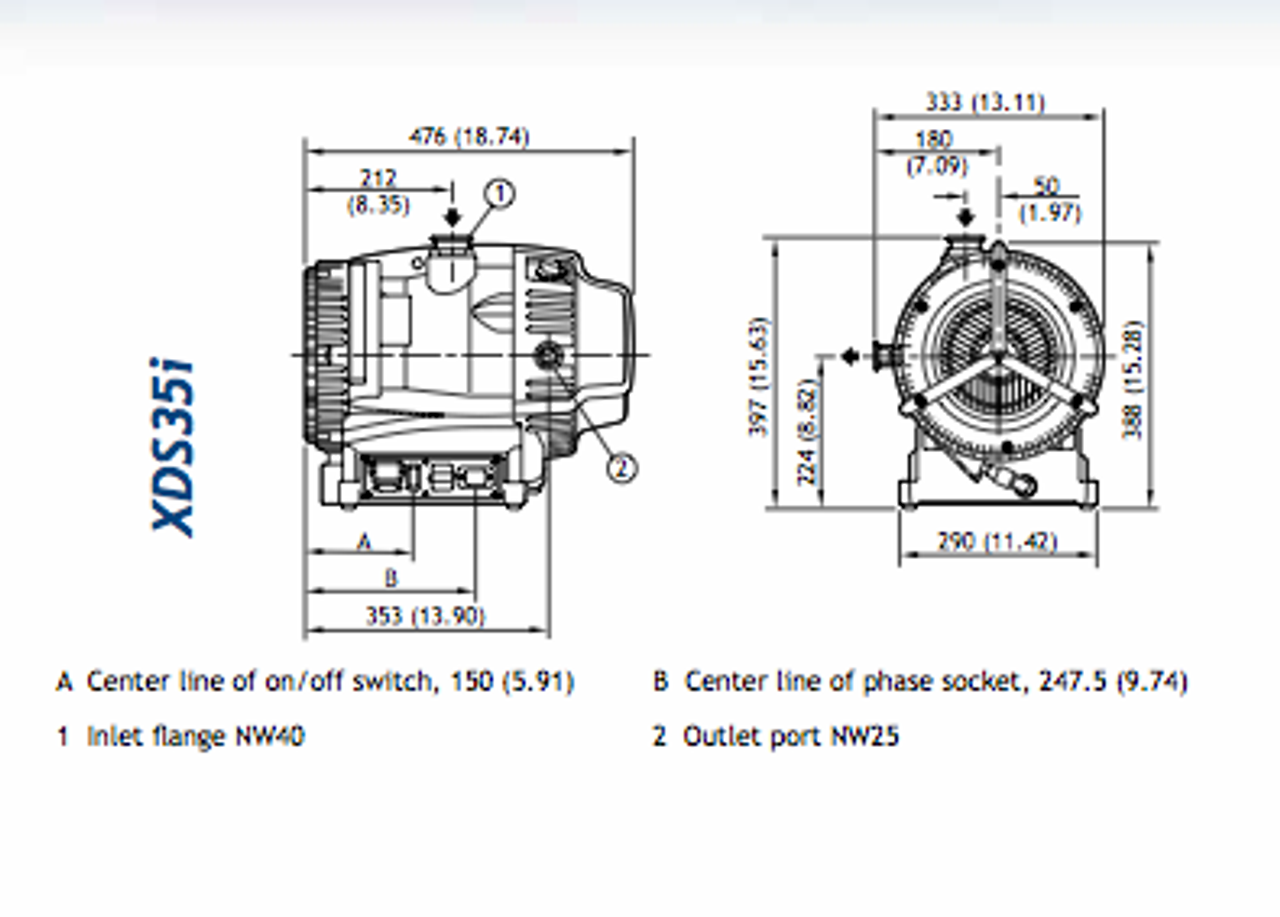

| Inlet flange | NW40 |

| Exhaust flange | NW25 |

| Noise level | 57 dB (A) |

| Vibration | <4.5mms -1 (rms) |

| Leak tightness (static) | <1 x 10-6 mbar ls-1 |

| Operating temperature range | 10 to 40 °C / 50 to 104 °F |

* 1 bar gauge / 14 psig for short period of time only.

Overview

Gas ballast allows vapour to be handled and opens up the range of applications to many that were previously unsuited to scroll pumps. The inverter drive controls the motor characteristics and ensures the pump always runs at optimum speed

Features and Benefits

- Lubricant-free within the vacuum envelope and hermetically sealed means totally clean and dry vacuum to prevent cross contamination

- No atmosphere to vacuum shaft seals means bearings are completely isolated, which prevents process attack and means the bearings run cooler and last longer

- Simple single sided scroll arrangement combined with an innovative motor and bearing design allows for easy field service with a minimum of special tooling for low cost of ownership and maximum up-time

- Improved motor and drive efficiencies for reduced power and cost of ownership

- Advanced interface provides a variety of traditional, analogue and digital control methods enabling remote control/monitoring via USB, RS232 or RS485

Applications

- General clean pumping applications

- Scanning Electron Microscopes - SEM

- Beam lines and high energy physics

- Backing turbo pumps

- Centrifuges, ultra-high speed

- Coating

- Cryogenics

- Degassing/curing - oil, epoxy resin

- Distillation/extraction/filtration

- Freeze drying

- Furnaces

- Gel drying

- Laboratory bench top vacuum

- Lasers, gas recovery and recirculation

- Leak detectors, Helium

- Load locks and transfer chambers

- Rare gas recirculation

- Rare gas recovery

- Refrigeration manufacture

- Research and development

- Rotary, centrifugal evaporators

- SEM/FIB (ion beam repair)

- Solvent recovery

- Surface science instruments