Product Description

SOGEVAC

Single Stage Oil Sealed Rotary Vane Pumps

The standard version of the SOGEVAC rotary vane pump series is suitable for rough industrial applications which can be customized to fit individual customer needs. A wide range of monitoring accessories and options are available. Different motor versions, inlet or exhaust ports, food-grade oil, food-grade paint, larger gas ballast are some examples of possible customizing.

Technical Data

Product: SOGEVAC SV 1200 ‐ with gas ballast valve

Part‐No.: 95070

Inlet connection: ASA 150 ‐ 6"

Outlet connection: ASA 150 ‐ 6"

Nominal pumping speed at 50 Hz: 1.150 m3/h 677 cfm

Nominal pumping speed at 60 Hz: 1.150 m3/h 677 cfm

Pumping speed at 50 Hz: 1.070 m3/h 630 cfm

Pumping speed at 60 Hz: 1.070 m3/h 630 cfm

Ultimate partial pressure without gas ballast: ≤ 1.0 x 10‐1 mbar ≤ 7.5 x 10‐2 Torr

Ultimate total pressure without gas ballast: ≤ 1.0 x 10‐1 mbar ≤ 7.5 x 10‐2 Torr

Ultimate total pressure

with one gas ballast valve: ≤ 1.5 mbar ≤ 1.1 Torr

with two gas ballast valves: ≤ 2.0 mbar ≤ 1.5 Torr

Water vapor tolerance at 50 Hz

with one gas ballast valve: 20.0 mbar 15.0 Torr

with two gas ballast valves: 40.0 mbar 30.0 Torr

Water vapor tolerance at 60 Hz

with one gas ballast valve: 20.0 mbar 15.0 Torr

with two gas ballast valves: 40.0 mbar 30.0 Torr

Water vapor capacity at 50 Hz

with one gas ballast valve: 12.5 kg/h

with two gas ballast valves: 25.0 kg/h

Water vapor capacity at 60 Hz

with one gas ballast valve: 12.5 kg/h

with two gas ballast valves: 25.0 kg/h

Operating fluid: GS 77

Operating fluid capacity

min.: 60 l 63 qt

max.: 70 l 74 qt

Noise level to DIN 45 635

at 50 Hz: 75 dB(A)

at 60 Hz: 75 dB(A)

Mains connection: 3‐ph, 208‐230/460 V, 60 Hz

Motor rating at 50/60 Hz: 22 kW 30 HP

Rotation speed at 50 Hz: 1.460 min‐1 1.460 rpm

Rotation speed at 60 Hz: 1.750 min‐1 1.750 rpm

Motor protection rating: IP 54‐F / TEFC

Admissible ambient temperature: +12 to +40°C +54 to +104°F

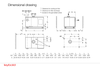

Dimensions: see dimension sheet

Weight: 1.370 kg 3.021 lbs

Technical data are subject to change

Copyright © Oerlikon Leybold Vacuum GmbH