Product Description

iH80 Dry Pump 460V, 60 Hz 3Ø

iH Dry Pumps

The Edwards iH dry pumps offer a highly reliable, low cost pump for difficult processes where particulate, condensable or corrosive by-products are present. The iH series has a five stage base pump with an innovative cantilever rotor, claw and roots design which improves dust handling and reduces exhaust noise. In addition, iH series pumps are fitted with a single stage mechanical booster pump and totally enclosed water cooled motors.

Technical Data

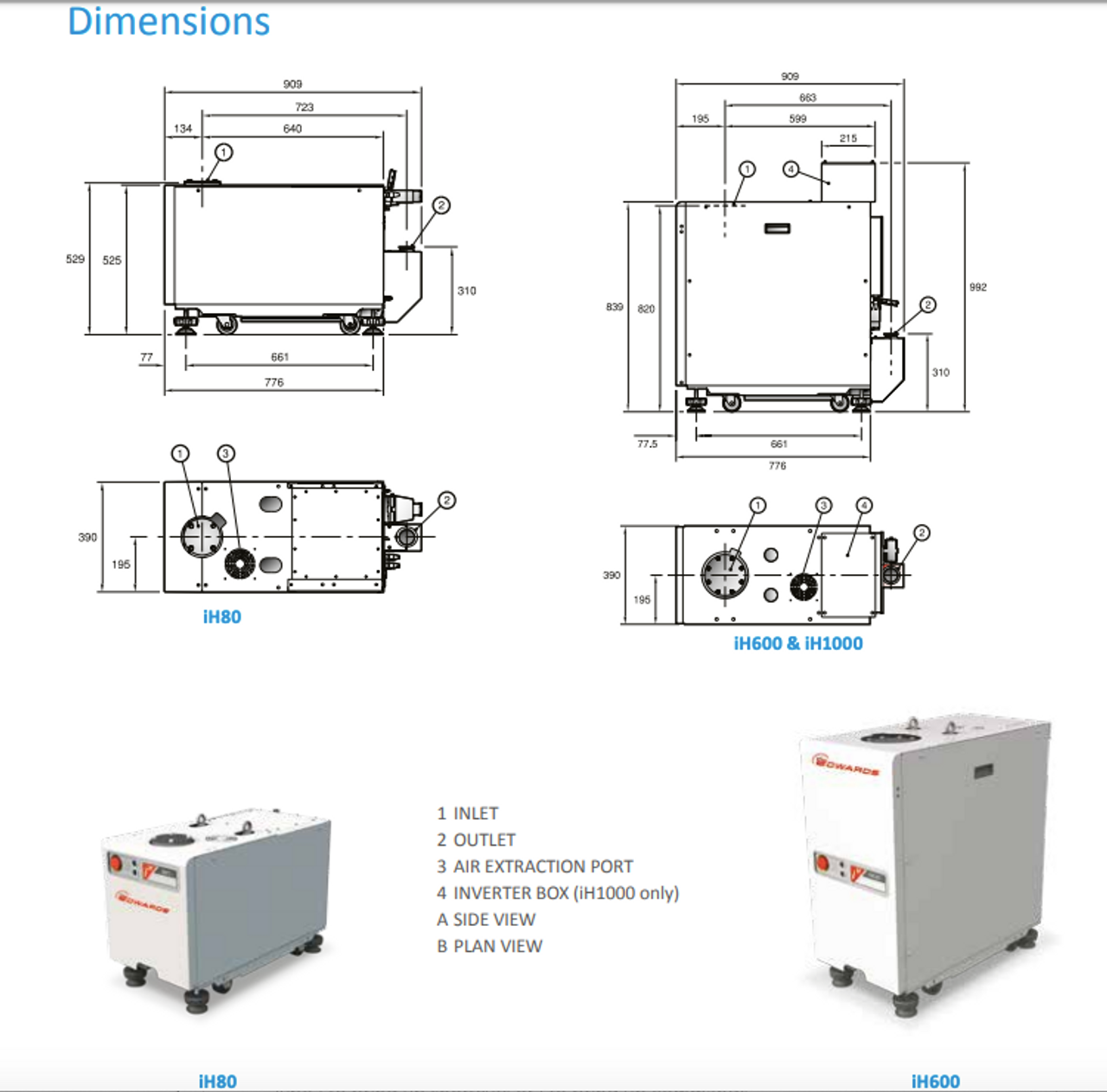

| Models | iH80 | iH160 | iH600 | iH1000 | iH1800 |

|---|---|---|---|---|---|

| Peak Speed | 103 m3h-1 | 165 m3h-1 | 600 m3h-1 | 1000 m3h-1 | 1800 m3h-1 |

| 61 cfm | 97 cfm | 353 cfm | 589 cfm | 1060 cfm | |

| 1717 l min-1 | 2750 l min-1 | 10000 l min-1 | 16670 l min-1 | 30000 l min-1 | |

| Ultimate Vacuum | 1 x 10-2 mbar | 7 x 10-4 mbar | 1 x 10-3 mbar | ||

| 7.5 x 10-3 Torr | 5.3 x 10-4 Torr | 7.5 x 10-4 Torr | |||

| 1 Pa | 0.07 Pa | 0.1 Pa | |||

| Typical shaft seal nitrogen flow | 4 slm | ||||

| Inlet Connection | ISO63 | ISO100 | |||

| Outlet Connection | NW40 | ||||

| Typical cooling water flow at 15 psi pressure drop |

120 l h-1 | 240 l h-1 | |||

| 2 l min-1 | 4 l min-1 | ||||

| Weight | 240 kg | 244 kg | 415 kg | 430 kg | 502 kg |

| Power input at ultimate | 2.7 kW | 3.1 kW | 3.4 kW | 3.8 kW | 4.1 kW |

| Rated motor power | 3.5 kW | 5.0 kW | 6.1 kW | 6.1 kW | 7.0 kW |

| Oil Capacity | 0.7 l | 0.85 l | 1.43 l | 1.48 l | 1.6 l |

Overview

The iH Series offers high reliability for difficult processes, such as PECVD and LPCVD, where particulate, condensable and corrosive by-products are present.

Technology

The iH80 system has an HCDP80 dry pump; The HCDP pump has enclosed, water-cooled motors. The iH system is therefore suitable for applications in clean environments where fan cooling of motors is unacceptable.

The iH system has a gas system which introduces purge gas into the HCDP pump. This gas system is suitable for use on harsh duty processes. If you use the iH system on light or medium duty processes, you can use the economiser gas mode to reduce the consumption of purge nitrogen by the pumping system.

You can manually control the iH system through the Pump Display Terminal. Alternatively, you can use your process tool or other control equipment to control the operation of the iH system through an Interface Module or through an iM Communications Module accessory or you can use the iH Single Equipment Monitor accessory to control the operation of the iH system.

Applications

- Load Lock

- Transfer

- Metrology

- Lithography

- PVD Process

- PVD Pre-clean

- RTA

- Strip/Ashing

- Etching

- Implant Source

- HDP CVD

- RTP

- SACVD

- MCVD

- PECVD

- LPCVD

- ALD

| 200/208 V | 230 V | 380/415 V | 460 V | |

| 50/60 Hz | 60 Hz | 50 Hz | 60 Hz | |

| iH80 | A59000945 | A59000957 | A59000946 | A59000908 |

| iH160 | A59010945 | A59010957 | A59010946 | A59010908 |

| iH600 | A59020945 | A59020957 | A59020946 | A59020908 |

| iH1000 | A59030945 | A59030957 | A59030946 | A59030908 |